With the help of advanced laser cutting technology, SLD Precision provides advanced rapid prototyping services which are mainly focused on creating accurate prototypes that fulfill your specific requirements and design needs.

Our rapid prototyping services cater for different needs such as product designing or functional tests. In order to enable our customers develop new Products, work with concepts or improve existing models; we ensure that prototypes produced by SLD Precision exhibit exceptionally high level of accuracy and speed.

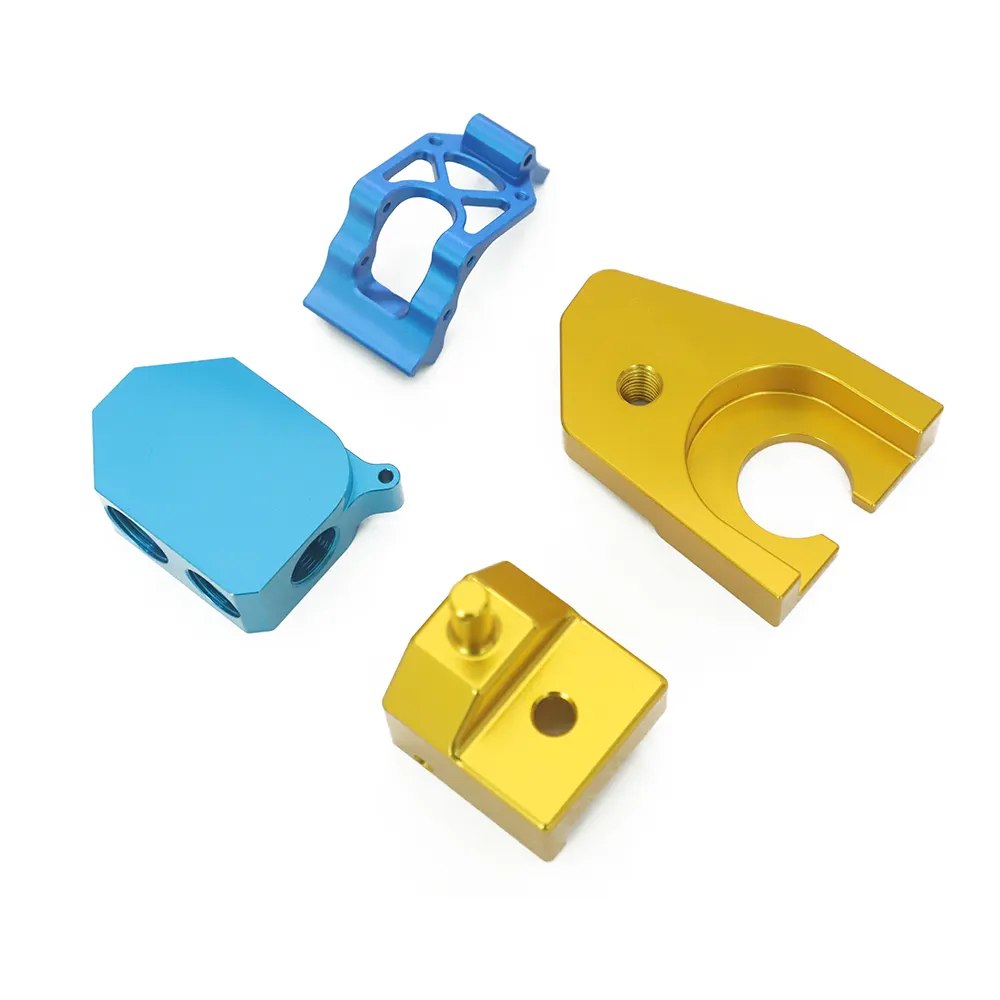

We have the ability to work on various materials such as metals, plastics and composites using our state-of-the- art laser cutting machines thus producing prototypes that are highly detailed and accurate. Our technology can be used to create complicated designs and geometries which may be difficult to achieve through traditional methods. This level of precision and flexibility makes SLD precision an ideal partner in a range of industries from automotive industry, aerospace to consumer electronics sectors among others.

SLD Precision recognizes the significance of timely delivery during the prototype phase. Competing in fast paced marketplaces necessitates streamlined operations and efficient turn around times this will enhance constant iterations , faster decisions. As a result our experienced team is dedicated towards delivering top notch customer service as well as quality results thereby ensuring that maximum attention is paid when dealing with prototype need’s details.

SLD Precision is the company that centers on quick prototyping, which our clients can benefit from. The time it takes to develop a product is reduced by speedy prototyping and allows for rapid modifications and reworkings. By using the latest techniques in CNC machining, 3D printing, and sheet metal fabrication, fast prototypes of high quality can be produced. Such an approach enables us to perform comprehensive testing of every aspect of a new design prior to its being put on the market and helps us confirm its operation.

When you choose SLD Precision for your rapid prototyping requirements, you are guaranteed the best expertise in the industry and access to cutting-edge technology. Our services for fast prototyping enable faster verification of design which leads to quicker decision making and reduced development costs. Advanced CNC machining and 3D printing are employed by us so as to produce functionally operative prototypes which have high levels of detail. Our prototypes are made in accordance with your specifications and conform to quality norms thus can be relied upon for testing purposes.

SLD Precision’s quick prototyping services will help you advance your product development process. Our proficiency in CNC machining and sheet metal fabrication guarantee the development of accurate functional models. Early design testing and validation is done through rapid prototyping, allowing for necessary adjustments before final production. By doing this, the approach not only speeds up developments but also minimize risks associated with design flaws which are costly. Work alongside SLD Precision so as to take full advantage of our rapid prototype capabilities ensuring that your Products will perform to their maximum potential right from inception.

With various industries diverse needs in mind, we at SLD Precision provide up-to-date rapid prototyping solutions. Our cutting-edge prototyping services equip companies with tools to help them quickly and efficiently design, try out and refine their Products. Rapid prototyping is paramount in sectors such as aerospace, automotive, healthcare and consumer electronics; as it makes it possible for one to come up with high fidelity prototypes that resemble final products and gives insights on form, fit and function. At SLD Precision our prototype services are marked by accuracy, multi-functionality as well as swiftness which guarantees the best quality and performance of every prototype manufactured.

Shenzhen SLD Precision Hardware Co.,Ltd was founded in 2018, We are specialized in cnc machining services and Sheet metal fabrication,CNC Parts,CNC Machining,Laser Cutting Service,Injection moldingOur company's advantage is that MOQ is 1 pcs and competitive price and fast delivery, We have YVM, Altitude, Rockwell hardness tester, Caliper, Roughness tester equipment to strictly control the product quality, In order to make sure the critical dimensions, we import our machines from the Germany and Japan. The minimum tolerance we can make is 0.01 millimeter.

Adhering to the business principle of mutual benefits, we have had a reliable reputation among our customers because of our professional services, quality Products and competitive prices. We have already built good business relationships with our customers in the United States, England, France, Germany, Canada, New Zealand, Italy, Hungary, Australia, Poland and Switzerland.

We warmly welcome customers from at home and abroad to establish cooperation and create a bright future with us together.

High-accuracy machining for complex components.

Utilizes cutting-edge CNC machinery for top performance.

Tailored solutions to meet specific customer needs.

Rigorous testing ensures reliability and durability.

Streamlined processes reduce lead times and costs.

Firstly, it accelerates the design process by allowing quick iteration and modification of prototypes. This speed helps in identifying design flaws early and ensures that final products meet user requirements effectively. Secondly, rapid prototyping can significantly reduce development costs by minimizing the need for expensive tooling and manufacturing processes. Additionally, it enhances collaboration among team members by providing tangible models that can be easily shared and reviewed. With SLD Precision's state-of-the-art technologies, you can expect high-quality, accurate prototypes that drive innovation and efficiency in your product development cycle.

At SLD Precision, accuracy and quality are paramount in our rapid prototyping services. We utilize advanced 3D printing technologies and precise CNC machining to produce prototypes with exceptional detail and fidelity. Our team of experts rigorously monitors each step of the prototyping process, from initial design to final production, to ensure that every prototype meets the highest standards. Additionally, we employ quality control measures such as dimensional analysis and material testing to guarantee that prototypes not only match the original design specifications but also perform well under real-world conditions.

Common materials used in rapid prototyping include plastics like ABS and PLA, as well as metals such as aluminum and stainless steel. At SLD Precision, we select materials based on the specific requirements of each project, including the prototype's intended use, required mechanical properties, and budget constraints. We offer a range of materials, including high-strength polymers and advanced composites, to cater to various applications. Our material selection process involves assessing factors such as durability, flexibility, and thermal resistance to ensure that the final prototype aligns with your project needs and performs optimally.

The turnaround time for rapid prototyping projects at SLD Precision depends on the complexity of the design and the specific requirements of the prototype. Generally, we aim to provide preliminary prototypes within a few days to a week. For more intricate or large-scale projects, the timeline may extend accordingly. Our streamlined workflow and efficient processes are designed to expedite production without compromising quality. We work closely with our clients to establish clear deadlines and ensure that prototypes are delivered on time to support your project milestones and development schedules.

SLD Precision is equipped to handle both low-volume and high-volume rapid prototyping needs. For low-volume projects, we offer flexible solutions that allow for quick adjustments and iterations, which is ideal for prototype testing and initial market validation. For high-volume needs, we provide scalable production capabilities that maintain consistent quality and precision across large quantities. Our advanced technologies and expertise enable us to efficiently manage varying production scales, ensuring that all prototypes meet the required standards, regardless of the volume.